Wire bonding is a common, but very important, process for connecting photonic integrated circuits (PICs) with their surrounding electronics. The recently acquired Royce Instruments 620 pull-shear tester allows PHIX to pinpoint weaknesses in the process and materials and ensure repeatable high quality wire bonds for large manufacturing volumes.

Wire bonding at PHIX

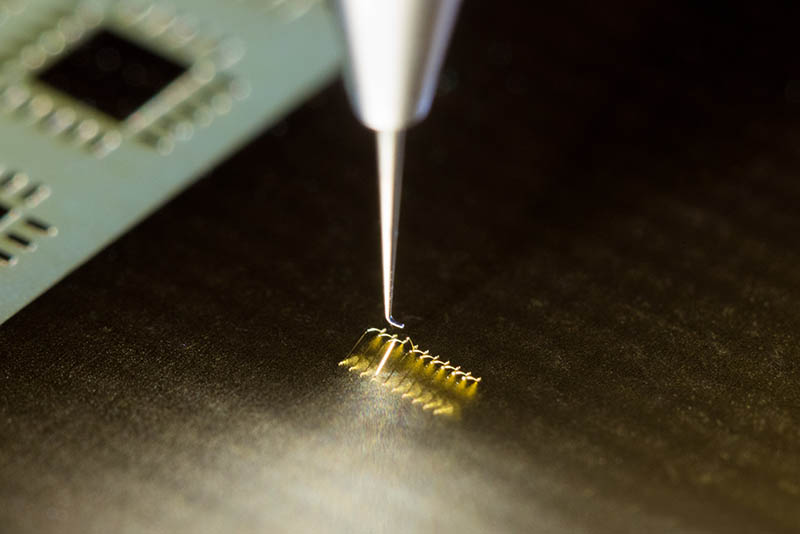

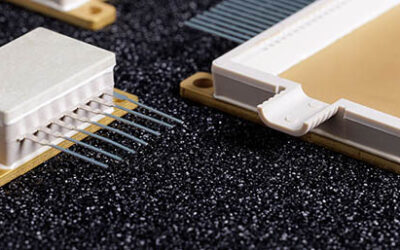

Modules based on photonic integrated circuits (PICs) often contain electrical interfaces for providing power or enabling read-outs. The most common method for making these connections between PICs and their surrounding electronics or housings are wire bonds. PHIX mostly uses wedge bonding of 17 μm gold wire, a process in which the bonds are formed with a combination of force and ultrasonic energy.

Wire bonds are inherently fragile and are usually protected by glob top encapsulation and/or hermetic sealing if the module is used in commercial applications. However, this doesn’t remove the need for a well-controlled wire bonding process that produces consistently good welds. Pull testing is a valuable tool to ensure that the process is set up for success when production starts, and remains robust during volume manufacturing in multiple batches.

Short clip of automated wire bonding at PHIX

Pull testing for wire bonds

The pull testing procedure that we perform on our Royce Instruments 620 pull-shear tester places a hook underneath the wire bond being tested and pulls it straight up. We measure the pulling force at which the bond fails and determine the mode of failure. This is destructive testing. Non-destructive testing, on the other hand, simply determines if a wire bond is strong enough to withstand a specified pulling force. The rest of this article refers to destructive pull testing.

Pull test failure modes

Even more than the force at which failure of a wire bond connection occurs, the failure mode reveals a lot about the quality of the bond and any flaws in the source and destination materials. We distinguish eight different failure modes, as illustrated in the gallery below.

Provided that the required force is consistent with the wire’s specified tensile strength, failure modes 1 to 3 generally indicate a successful bond. The wire itself is the weakest link, which demonstrates a solid weld to the bond pads.

If the wire comes loose from the pad, like in failure modes 4 and 5, then the quality of the weld may be insufficient. This could indicate that process parameters like ultrasonic energy or bond force need to be optimized further. Another cause could be excessive oxidation of the bond pad or a poorly suited stackup of metallization and barrier layers.

Cratering or pad liftoff, which occurs in failure mode 6, indicates a problem with the integrity of the photonic integrated circuit, where the adhesion layer between the bond pad and the substrate is too weak.

If the pulling force drops to zero but no failure has occurred, as in mode 7, then the pull test itself is invalid and will need to be repeated. Mode 8 represents other possible problems, such as failure of the adhesives between the PIC and submount.

How pull testing supports your module manufacturing

For volume packaging of integrated photonics or MEMS we can perform pull tests for each batch. This allows us to reveal variations between batches of PICs or housings and quantify the influence of tool wear. We can then correct for these variations by modifying the process parameters and issue a warning to the customer if we notice quality drops in source materials. This enables PHIX to achieve a high quality standard for our wire bonding process that is fit for volume manufacturing of a large variety of PIC and MEMS based modules.

“Our pull testing experiments help us optimize wire bonding process parameters, so that we can deliver high quality optoelectronic modules in large manufacturing volumes.”

Jan Pieter Hammink

Wire bonding specialist

Discover photonics packaging and contract manufacturing at PHIX

Wire bonding is an integral part of PHIX’s PIC and MEMS assembly services, both for prototype series and volume production. We also make our processes available for contract manufacturing, so that you can outsource or second-source (parts of) your production to PHIX. Besides wire bonding we have skills and equipment for other high precision microassembly processes, such as flip chip die bonding and optical fiber attachment.