As part of the PHOTO-SENS consortium, PHIX is working on enabling the industrialization of a flexible and cost-saving photonic biosensing platform. This project involves hybrid integration of light sources, photodiodes, and microfluidics with chemically coated photonic integrated circuits.

A powerful and flexible lab-on-a-chip

Photonic integrated circuits (PICs) are rapidly finding their way into various types of medical and sensing devices, due to their potential for high performance at low costs. An example of such a promising application is the PHOTO-SENS silicon nitride based photonic biosensor that detects molecules by measuring changes in the refractive index of its waveguides. Some technical details of this detection process are described in this article. The PIC is to be packaged into a disposable microfluidic cartridge that can be inserted into a portable read-out system. The advantages of this lab-on-a-chip photonic technology are threefold:

- It offers high accuracy at low cost

- It’s a field test with an immediate result, without the need for a laboratory

- Countless applications are possible simply by changing the surface chemistry

With the participation of Tunatech, the PHOTO-SENS project concentrates on developing a biosensor for DNA-based aquaculture diagnostics. For example, the sensor allows routine testing for an early detection of pathogens in the water environment of salmon farms. This improves the health of the fish and reduces the need for antibiotics. By replacing the surface chemistry, countless other uses of this biosensor platform become possible, such as cancer and COVID tracking, food quality analysis, and gas detection.

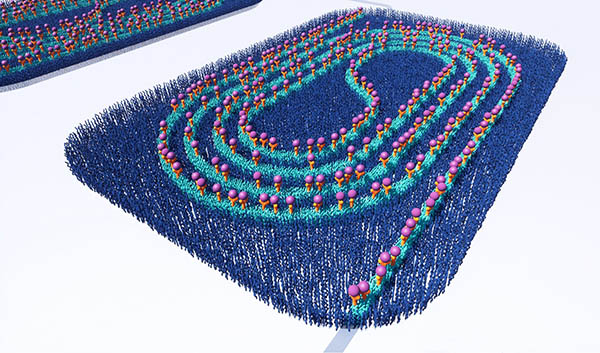

A material-selective coating causes the molecules to be detected to only bond to the waveguide of the chip. Image courtesy of Surfix Diagnostics.

Hybrid integration

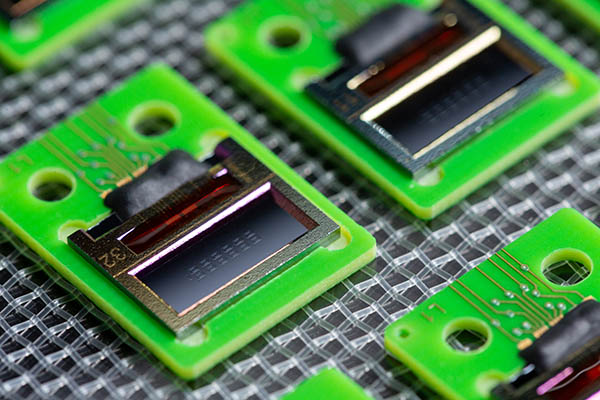

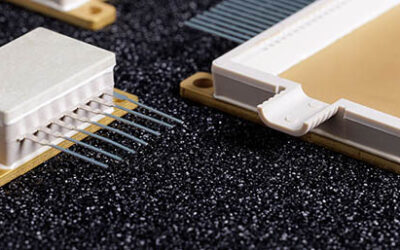

Building on an earlier prototype biosensor, PHOTO-SENS also focuses on minimizing the manufacturing costs of the photonic cartridge. The assembly process of the cartridge involves the integration of the SiN photonic integrated circuit with the light source (VCSEL), detector (photodiode), electronic printed circuit board, and the microfluidic interface. In addition, the material-selective nanocoating needs to be applied and functionalized.

To maximize the manufacturing throughput, it is beneficial to perform as many of these assembly steps at wafer level. PHIX is already very experienced with hybrid assembly processes, but is developing novel bonding strategies that do not degrade the chemical surface treatment.

Photonic biosensor prototype manufactured by PHIX for the BIOCDx project

A multi-disciplinary European consortium

Apart from PHIX and the aforementioned Tunatech, the PHOTO-SENS consortium includes three other partners. Dutch company Surfix Diagnostics produces the photonic integrated circuits and is responsible for coating and chemically functionalizing them. CSEM is a Swiss research and technology organization that provides the microfluidic solutions. The German company LRE Medical is developing the portable read-out system.

The five companies have just been awarded a Fast Track to Innovation (FTI) grant of €3M by the European Commission to further the industrialization of this photonic biosensor platform.