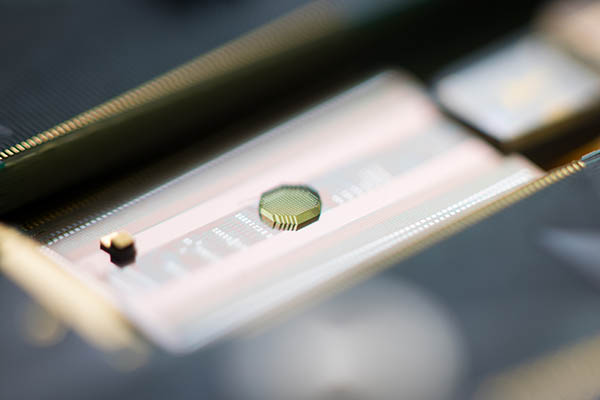

3D Microfabrication

3D printing of microstructures

Using our Nanoscribe Quantum X align tool we can 3D print optical and mechanical microstructures directly onto surfaces such as fiber cores or photonic integrated circuits (PICs). Some example applications are:

- Lensed fiber arrays (product page)

- (Arrays of) microlenses on PIC surfaces or edges

- Prisms or other freeform optical structures

- Microfluidic or micromechanical structures

256-microlens array printed onto a photonic integrated circuit grating coupler

The microfabrication process

This high-precision additive manufacturing process for microstructures is based on two-photon polymerization (2PP), in combination with state-of-the-art alignment technology. It enables a feature size down to 100 nanometers, with optical grade surface quality free from slicing steps. This allows full control over the optical properties of the printed optics. Not only can lenses be designed to focus or collimate light, but they can even take on aspherical shapes in order to correct for optical aberrations.