Market: 5G and beyond

Mobile data explosion

In recent years the traffic volume of mobile data has been experiencing a year-on-year growth of at least 50%*. Right now, the demand for 5G wireless technology is driven by voice and video mobile communications, but very soon the influence of autonomous vehicles, private networks and real-time industrial applications will be added to the mix.

Autonomous cars equipped with multiple LiDARs, radars, cameras, and other data-driven technologies are estimated to generate up to 4 TB of data every day. A significant portion of that data is expected to be shared with other vehicles and Smart City infrastructure, or stored for AI learning and accident analysis. This calls for a wider adaptation of 5G connectivity and future technologies that move into the terahertz range.

5G vs 4G

The 5G technology employs beamforming antenna arrays that create multiple Radio Frequency (RF) beams that are focused and steered towards surrounding mobile devices. Such steering allows all the energy that contains communication data to be focused to a receiver element. A 4G antenna element, on the other hand, radiates in all directions and communicates to all devices simultaneously. By shaping and redirecting the RF millimeter wave bundle, 5G requires lower radiation powers and achieves higher bandwidths that can dynamically be directed to specific subscribers. Another 5G advantage is that the information is not shared with all neighboring devices, making the communication more secure.

Integrated photonics advantages

Although 5G communication can be achieved using electronic chips, integrated photonics microwave beams have the advantage of being more broadband and providing more link gain than their electronic counterparts. For on-chip delay lines the phase delay is frequency-independent, so that each antenna element can be very accurately controlled. Because the RF signal is converted to an optical signal on chip, broadband gain can be easily achieved by integrating optical amplifier elements.

The use of integrated photonics also enables innovations such as the use of optoelectronic mobile network nodes in unmanned aerial vehicles (drones) as envisioned in the European research project TERAWAY, in which PHIX is a packaging partner.

PIC packaging challenges

The advantages of introducing photonic integrated circuits (PICs) into RF electronic systems can only be realized if the resulting optoelectronic modules are highly reliable, robust, and cost effective. Some of the challenges encountered for the packaging of these PICs are:

Minimizing signal degradation

In order to minimize signal degradation through losses and electromagnetic interference, the paths of the electronic (RF) components in the optoelectronic module should be designed carefully. Such optimization starts already at the PIC design stage, while also weighing in the manufacturability of the resulting module. For example, wire bonds between a PIC and PCB should be kept at a minimum length and impedances of both ends should match carefully to avoid reflections, losses, radiation, and noise. For this reason it is highly recommended to let PHIX advise you early on in your design process.

Hybrid integration of several PIC platforms

For many applications of integrated photonics it is beneficial to combine several material platforms, such as indium phosphide and silicon nitride, in order to take advantage of the best properties of each one. Such hybrid assembly requires processes for edge coupling or flip chip assembly of these PIC materials. After optimizing the module design for manufacturability, PHIX can perform and scale up these steps on automated equipment with great accuracy and reproducibility.

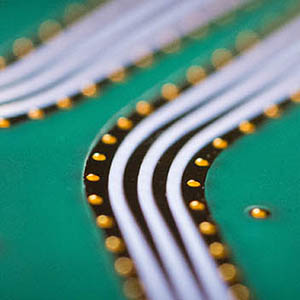

Thermal management

Requirements for miniaturization while using several different areas of the chip for electrical, optical, and mechanical interfacing can make heat dissipation and thermal management a challenge. PHIX has extensive thermal design expertise, using both commercial and in-house software for running simulations and selecting the right thermoelectric cooler (TEC).

Mass production at low cost

Despite the fact that PIC-based modules offer many advantages over pure electronics, their cost must be able to compete as well. When PICs scale to volume they have a low price per surface area, similar to their electronic counterparts. Packaging, assembly and testing, however, are traditionally an expensive step in the integrated photonics value chain. These costs can be made competitive if the assembly processes are well-defined and carried out on automated equipment. Another requirement is a carefully structured and optimized bill of materials. PHIX is happy to help define a roadmap towards cost-effective volume manufacturing.

How PHIX helps enable faster mobile networking

As well as serving our commercial customers, we are contributing our photonics packaging expertise to the European research projects TERAWAY and POETICS to tackle the challenges mentioned above for the mobile networking market. To support your optoelectronic module on the way to its maturity, we offer a range of standard and custom package types.

Our prototype packages are great for characterization and prototyping of your first designs. If you’re ready to ramp up production our volume packages may be even better suited. We can even provide help with your existing manufacturing, by running your processes on our automatic machines through outsourcing or second-sourcing. To follow the latest development of our company you can visit our news section.

I have a different question

* Source: Ericsson Mobility Report november 2020