July 10th 2024

Based on patented PHIX technology for integrating bulk optics with photonic integrated circuits (PICs), PHIX assembled a proof-of-concept optical isolator building block for the lithium niobate platform.

One of the goals of the Horizon Europe PATTERN research project is to develop new building blocks for the lithium niobate on insulator (LNOI) PIC platform. One such highly desired building block is an optical isolator, which can be thought of as the optical equivalent of an electronic diode. It allows light to propagate through it in one direction, while blocking its transmission in the other. This optical function is crucial for eliminating back reflections, for example when used in combination with external cavity lasers. Enhancing the performance of these chip-based lasers benefits a wide range of applications in the domain of integrated photonics, such as LiDAR, telecommunication, and metrology.

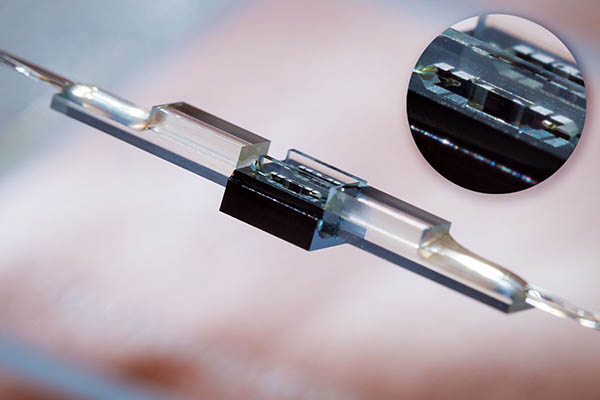

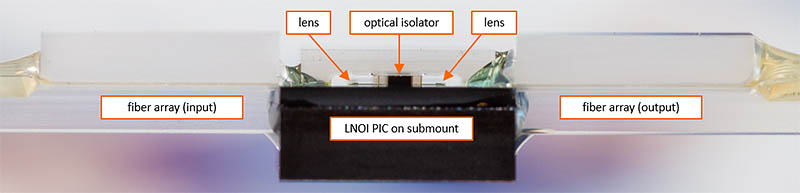

The proof-of-concept optical isolator device for the LNOI PIC platform demonstrated here utilizes patented PHIX technology for integrating bulk optics with PICs (NL2028885B1). In this particular application the optic is an isolator that operates in the C-band wavelength range, based on the physical principle of the Faraday effect. The device is constructed of the following components. Two fiber arrays serve as the optical input and output ports of the LNOI PIC, which is manufactured by CSEM. The PIC is attached to a submount for mechanical support and has a rectangular cavity made using a deep reactive ion etching (DRIE) process, thus introducing free space between the separated waveguides. An isolator chip based on nonlinear yttrium iron garnet crystal and a set of polarizers is positioned within this cavity using PHIX’s scalable pick-and-place assembly process. In order to efficiently transmit the optical signal between the waveguides through the isolator, the light is collimated by using a pair of microlenses 3D printed on the opposite facets of the cavity. The lenses are a product of PHIX’s 3D microfabrication process on the Nanoscribe Quantum X Align system, which enables 3D printing of microscopic features with advanced optical properties, submicron resolution, smooth surface quality, and high positioning accuracy.

While this proof-of-concept device features just one optical channel, this solution can scale quite favorably to multichannel fiber arrays. The isolator chip can cater for multiple optical channels at once, with each additional channel only requiring an extra pair of microlenses. In addition, this technique can be applied at wafer scale and will work for all major PIC platforms, not just lithium niobate.

“Future development of this heterogeneously integrated optical isolator device will focus on improving its optical performance by further reducing the insertion loss and increasing the isolation parameter. We will achieve this by optimizing the device design and implementing novel integration approaches. The development of new packaging solutions for the next generation of ultra‐high‐speed microwave PICs benefits both the research goals of the PATTERN project as well as PHIX’s commercial offering.”

Karol Obara

PHIX Photonic Design Engineer

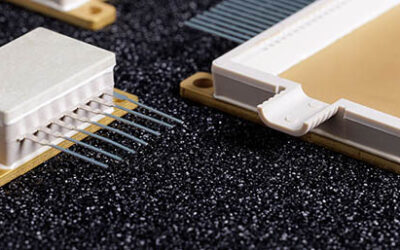

PHIX is a world leading pure play packaging foundry for photonic integrated circuits (PICs) of a large variety of material platforms. Besides LNOI, PHIX assembles optoelectronic modules based on silicon photonics, silicon nitride, indium phosphide, aluminum oxide, and several other material platforms. Find out more about PHIX’s photonics and MEMS packaging offering.

PATTERN is a Horizon Europe research project in partnership with Thales, CSEM, Imec, Fraunhofer HHI, Luceda Photonics, CNRS, Microwave Photonics, L-up, University of Cyprus, and UCL, scheduled for completion in 2026. It’s funded by the European Union under GA No. 101070506. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union. Neither the European Union nor the granting authority can be held responsible for them.