PHIX just unwrapped a brand new Finetech Fineplacer Femto 2 machine, a flexible fully automatic flip chip assembly workhorse that will further increase our manufacturing throughput. Furthermore, we are the first commercial company to obtain a customization within the Femto 2 which allows for localized heating. This allows hybrid assembly using laser soldering or thermocompression bonding without damaging nearby temperature-sensitive components.

Higher manufacturing throughput

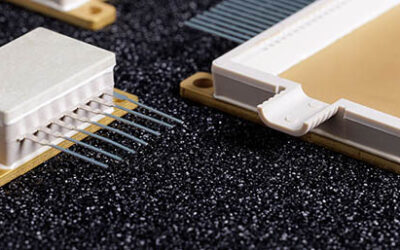

Where our partnership with ficonTEC produced an automatic production tool with active alignment for edge coupling of photonic chips, the Finetech Fineplacer Femto 2 allows components of different materials to be bonded vertically, using a passive flip chip configuration. We succesfully developed processes on the manual Finetech Lamba for manufacturing steps such as the mounting of a photonic integrated circuit or gain chip to a submount and integration of photodiodes and VCSELs. The Femto 2 enables a higher level of automation for these processes, allowing PHIX to ramp up existing processes to volume production.

New hybrid assembly applications

On top of its fully automated operation, the customized Femto 2 allows a very localized application of bonding heat using laser soldering. This opens up new possibilities for flip chip integrations. An example of a project in which we will put this to use is the packaging of the PHOTO-SENS photonic biosensor. The localized heating can prevent degradation of the temperature-sensitive chemical surface treatment that is crucial to the module’s functionality for applications that can replace PCR testing, such as cancer diagnostics or COVID-19 detection.

The arrival of the Fintech Fineplacer Femto 2 at PHIX