The TERAWAY project develops a new generation of terahertz transceivers for 5G wireless networks. These modules can be deployed on aerial drones to provide communications coverage at large outdoor events. As the photonics packaging partner in this project, PHIX is tackling important challenges in hybrid integration of multiple photonic components of different technologies, integration of terahertz antenna elements, and thermal management.

Airborne high-capacity links for 5G networks

Our move to a highly mobile and connected society is putting a large demand on emerging wireless network technologies in terms of coverage, capacity, reliability, and energy consumption. Terahertz (THz) wireless communication, with carrier frequencies in the 300 GHz range delivering an abundance of bandwidth, has a huge potential to meet these requirements.

The TERAWAY European H2020 5GPPP Phase III project, in which PHIX is a partner, is producing a set of groundbreaking transceiver modules based on integrated photonics. Among the prototypes in development are four-channel modules operating at frequencies up to 322 GHz, offering a wireless data transfer rate of up to 241 Gb/s with a transmission reach of more than 400 meters in the THz band. The transceivers can be mobile, relaying signals to and from fixed 5G towers using four independently steered wireless beams. In fact, in TERAWAY’s test scenario the transceivers will be mounted on heavy-duty drones. When flying over large outdoor events the drones can provide visitors with high bandwidth wireless communication, while the organizers, emergency services or law enforcement can monitor crowd movements, visitor health and safety with very high precision.

This research is carried out by a consortium of 12 partners from 6 EU countries. The role of PHIX is to provide the packaging of the transceiver modules, including the hybrid photonic integration, silicon antenna rod (array) attachment, and thermal management for multiple heat sources in a single package.

The photonics motherboard

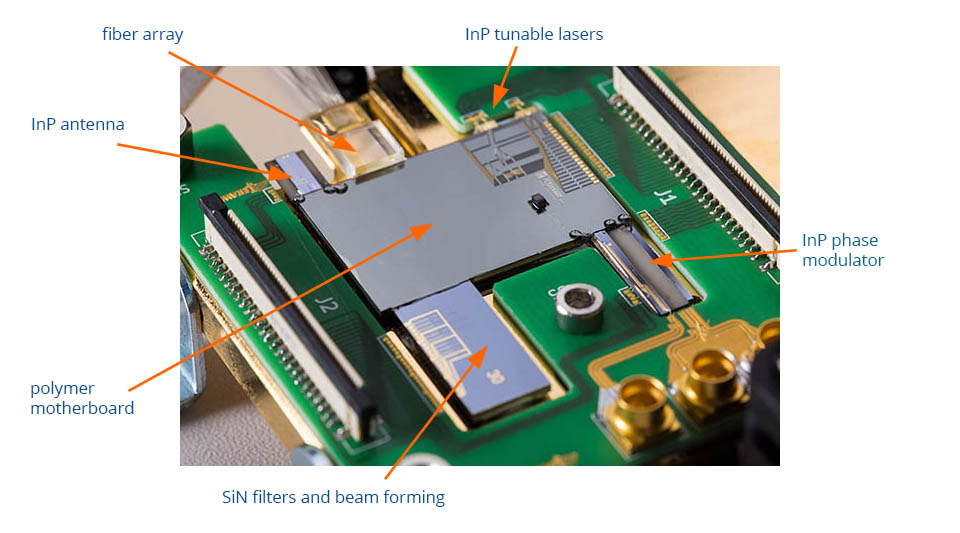

The THz transceiver consists of two modules, a transmitter and a receiver. Each module is based on a photonic motherboard concept that combines the best properties of multiple integrated photonic platforms. It provides optical coupling to the fiber array and brings the indium phosphide (InP) and the silicon nitride (SiN) components together. The optical subsystems are electrically connected to the printed circuit board via wedge-wedge circular and high speed RF ribbon wire bonds.

The photonic components in this assembly are edge-coupled using active alignment, where possible with waveguide alignment loops, and bonded with UV-cured adhesive. The design of such a multi-chip assembly and its individual photonic components incorporates several best practices that are described in the PHIX Design Guidelines document. For example, the electrical coupling is done at two opposite sides of the chip while the orthogonal sides allow for photonic interconnections to be made. Wherever multiple optical interfaces coexist on the same edge, sufficient clearances are maintained between them. Adhering to these packaging design principles allowed PHIX to achieve a first-time-right result when building the module prototypes.

“TERAWAY has introduced PHIX to photonics packaging in the THz domain. The process development for the manufacturing of the devices of tomorrow is further reinforcing our hybrid photonic integration capability and expertise, which benefits the commercial customers that we’re serving today.”

Zerihun Tegegne

Photonics Engineer and Project Manager

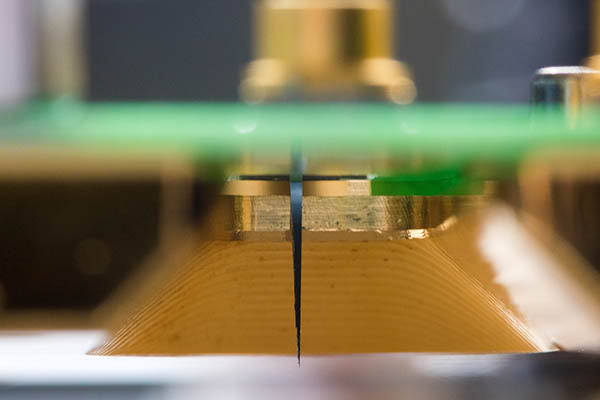

Antenna rod attachment

The antenna rods are attached on the unpatterned bottom of InP antenna chips. For this PHIX uses a flip-chip process and UV-cured epoxy. Because the machine’s regular vacuum chuck can only hold flat chips, we developed a dedicated vacuum tool to replace it, allowing for a precise alignment of the antenna rod and a smooth release after epoxy cure. The first TERAWAY prototypes use single antenna rods for each transmitter and receiver, but antenna rod arrays of 1×4 or 4×4 are planned for future modules.

Thermal management

This densely integrated design makes it hard to avoid placing thermally sensitive components, like tunable lasers, in proximity to components generating a lot of heat, like the drivers for phase modulators. Given that photonic components also generally have stricter operational temperature and stability requirements in comparison with electronics, the use of a Peltier element is required. PHIX used in-house software to determine the optimal thermoelectric cooler (TEC) parameters for this application. In this prototype further heat dissipation is achieved by two heat sinks, but the final design will likely employ heat pipes in combination with a single system-wide heat sink.

Discover prototype packaging at PHIX

Have you got a PIC-based innovation yourself and would like to know more about packaging and assembling it into an optoelectronic module prototype or demonstrator? Discover our prototype packaging options. We can also help plan your roadmap towards volume production of your technology.