January 27th 2025

In partnership with RJR Technologies PHIX offers LCP air cavity packages for integrated photonics. At high manufacturing volumes this packaging solution combines a low cost per unit with low packaging costs, by enabling multi-device strip-level assembly on leadframes.

Flexible volume packaging for integrated photonics

Liquid crystal polymer (LCP) air cavity packages have a proven industry track record in high-volume power electronics and RF applications in demanding automotive, sensing and consumer electronics markets. In collaboration with RJR Technologies, a technology and manufacturing company headquartered in Phoenix, Arizona, PHIX is now offering this packaging solution for integrated photonics applications.

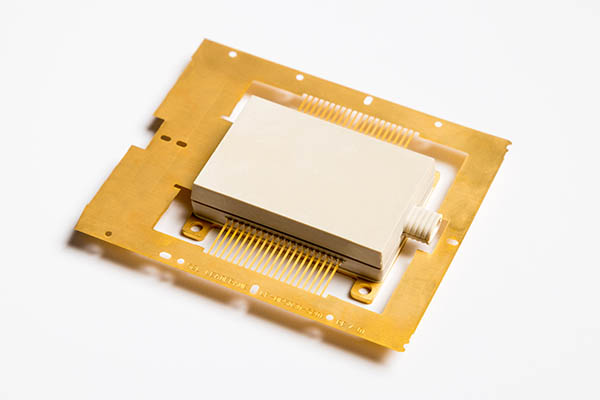

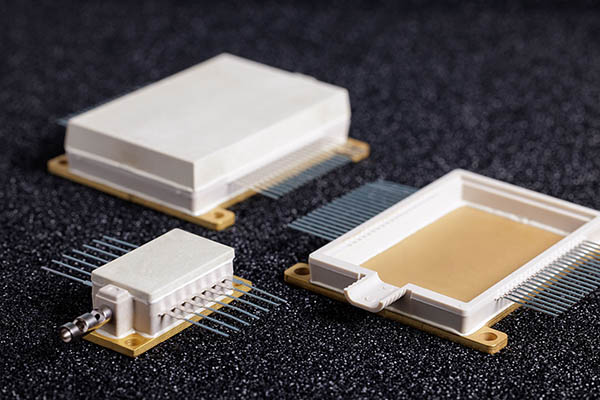

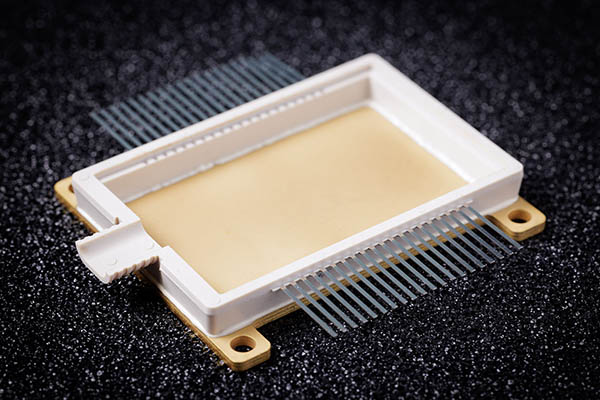

The LCP housing is injection molded around a lead frame and substrate with a near-hermetic seal, ensuring the longevity of your PIC-based devices in demanding use environments. The leadframe and substrate designs and materials can be customized to your needs, providing the appropriate electrical fanout for your PIC and a selection of substrate materials that provide an excellent thermal path and thermal expansion matching properties. The package can be configured as a traditional butterfly, or adapted to air cavity TROSA or QFN form factors.

This packaging solution provides excellent scalbility to high manufacturing volumes for two main reasons:

Low cost per unit

The cost per housing is significantly diminished in high volumes, because the initial non-recurring engineering (NRE), tooling, and setup costs can be divided over a large number of units. This greatly reduces the cost of the bill of materials (BOM) compared to solutions based on traditional copper alloy butterfly or gold box housings.

Low packaging costs

At high manufacturing volumes further cost scaling can be achieved in the packaging phase by employing multi-device strip-level assembly and batch handling. High throughput strip-level manufacturing is made possible by delaying lead frame separation until after device assembly. The adoptation of JEDEC format cassettes enable fast, easy, and accurate transfer of subassemblies between manufacturing equipment in a production line.

Tooled photonics packages available for technology evaluation

Our customers can evaluate if this LCP air cavity packaging solution is a good choice for their PIC-based device by making use of our tooled generic package, which has a similar form factor as our large area gold box. It offers an optical I/O for up to 32 fibers and 40 pins of DC electrical connectivity.

Please contact our sales team to discuss the possibilities for evaluating this high volume packaging solution in a prototype production run.