April 29th 2025

A multi-sensing solution based on photonic integrated circuits (PICs) developed by a European consortium is set to revolutionize the diagnosis of cancer and cardiovascular disease. As one of the partners, PHIX is pushing the boundaries of PIC packaging and 3D microfabrication to enable groundbreaking point-of-care medical devices.

A disruptive medical diagnostic platform

Extracellular vesicles (EVs) are nanoscale particles in the blood that play a key role in cell waste removal and cell-to-cell communication. They have been shown to carry biomarkers for conditions such as pancreatic cancer and cardiovascular disease. The detection of these biomarkers provides not only valuable information about the presence of these dangerous diseases, but also about their progression and the effectiveness of medical treatments. This makes EV analysis in blood samples one of the most impactful opportunities in the advancement of modern medicine.

A big challenge, however, is that EVs are typically sized between 50 and 200 nm. Current commercially available instruments struggle to detect particles smaller than 150 nm and are bulky, expensive, and not widely available. The goal of the PHOREVER project is to develop a point-of-care device with greatly improved detection performance, cost effectiveness, and portability. At the heart of this device is a 3-in-1 multi-sensing platform based on two photonic integrated circuits (PICs), stacked one on top of the other, which will be assembled by PHIX.

Multi-sensing solution combining photonics and microfluidics

The device under development in the PHOREVER project combines three photonic sensing methods:

- flow cytometry (FCM) for the detection and size classification of particles.

- fluorescence sensing for detection of the target biomarkers on the EV surface.

- optical coherence tomography (OCT) for additional microimaging and noise reduction.

The functions of FCM and fluorescence sensing will be combined together on the same PIC, whereas the OCT functionality will be realized on a separate PIC due to a different operating wavelength range.

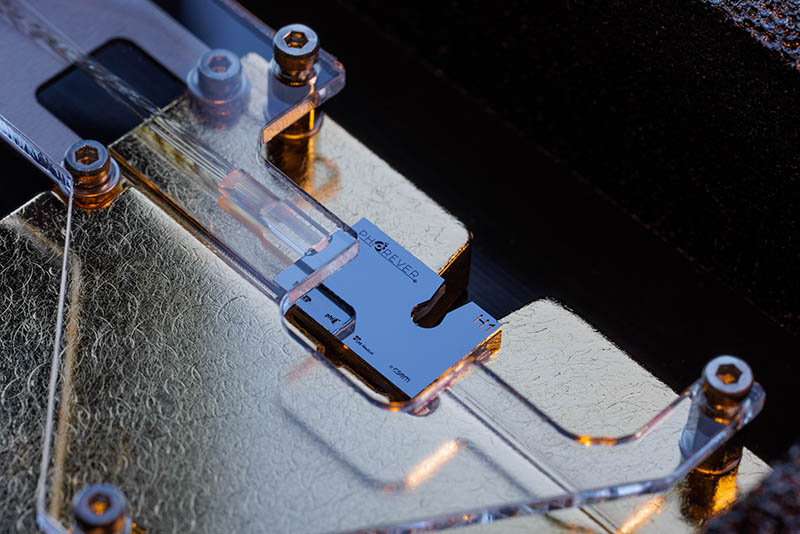

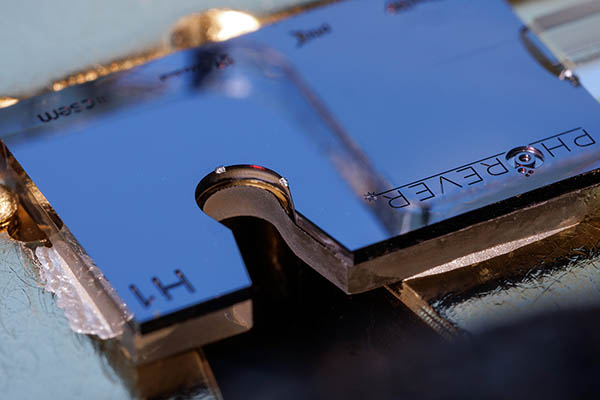

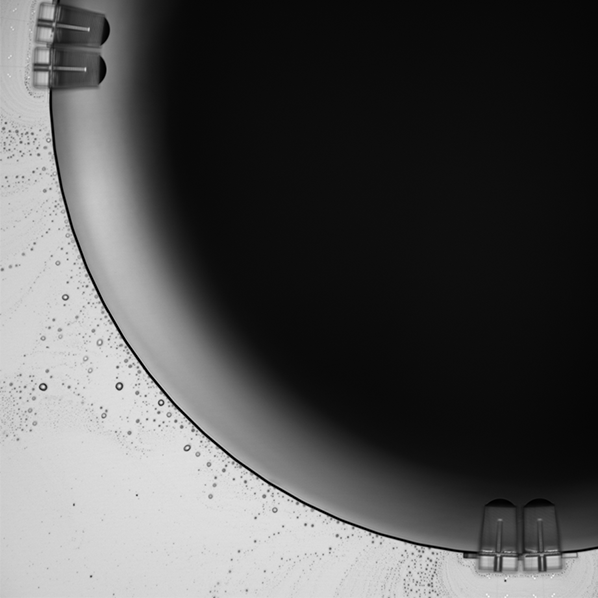

Both PICs are equipped with etched keyhole-shaped slots, which were fabricated to allow insertion of a glass capillary, through which a blood or plasma sample will flow. The glass capillary will be positioned in the center of the keyhole slots of both PICs in an active alignment procedure. This enables efficient transmission and detection of light for the successful interrogation of the sample.

“PHIX’s participation in PHOREVER not only contributes to innovations for early detection and treatment of diseases, but also helps us to further develop, expand, and industrialize our photonics packaging capabilities for commercial customers.”

Karol Obara

PHIX Photonic Project Leader

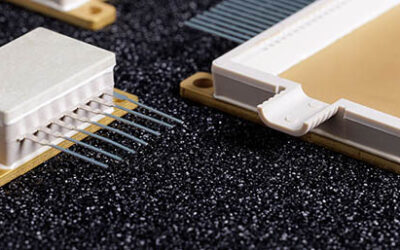

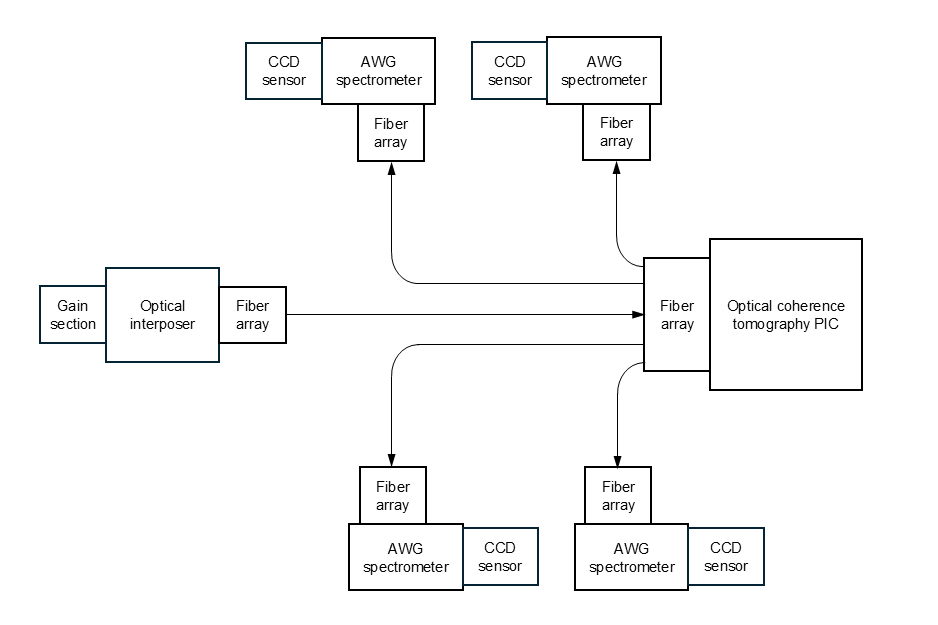

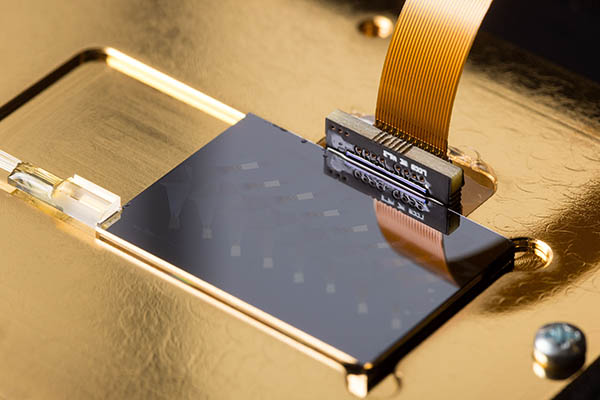

Apart from the assembled PIC shown in the image, the OCT system will be operated in a spectral domain that requires a broadband light source (a superluminescent diode) and two balanced photodetectors. Each photodetector is made up of two modules that consist of on-PIC arrayed waveguide grating (AWG) spectrometers and charge-coupled device (CCD) sensors. PHIX has successfully assembled all modules, which can be connected together with optical fiber arrays to demonstrate the described functionality.

Subsequently, the OCT submodule will be vertically stacked to another module that houses the PIC responsible for the FCM and fluorescence sensing functionalities.

Optical coherence tomography (OCT) system consisting of an OCT PIC, a superluminescent light source, and photodetectors

Photodetector consisting of a PIC-based AWG spectrometer and CCD sensor

Free space light propagation with 3D printed microlenses

Due to the PICs and the capillary not coming into physical contact, the transmitted and detected light will need to be propagated through free space. To enable this, PHIX used its 3D microfabrication capabilities to print microlenses on the side facets of the PICs. These microlenses, located inside the keyhole-shaped slots, focus the light from the waveguides onto the glass capillary and collect the scattered optical signal after its interaction with the sample.

The high-precision additive manufacturing process used to produce the microlenses combines two-photon polymerization (2PP) with state-of-the-art alignment technology, enabling the printing of microstructures with feature sizes down to 100 nanometers and optical grade surface quality. The microlens design parameters are highly configurable, so the optical efficiency of the system can be optimally finetuned.

The printing of microlenses on the PIC side facets requires careful consideration from the PIC designer, because the submicron printing positioning accuracy for the alignment of the microlenses and the waveguides can only be achieved if precise lens alignment markers are placed on the PIC surface during the layout phase.

The reliability of the microlenses when subjected to various levels of optical power and environmental conditions is also under investigation in the PHOREVER project. These studies allow PHIX to not only successfully demonstrate its processes for 3D lens printing on the side facet of PICs, but also perfect them for industrial applications.

Other photonics packaging challenges

Other challenges of the PHOREVER project that are driving PHIX toward making novel advancements in photonics packaging are,

- Vertical stacking of PICs and complex system integration.

- Mechanical polishing of large-surface PICs.

- Optical coupling for high power signals in the visible wavelength range.

The (improvements of) photonics packaging processes developed in this project will strengthen and expand PHIX’s commercial offering and contribute to the global industrialization of PIC technology.

PHOREVER is a Horizon Europe research project with 8 partners, scheduled for completion in 2026. It’s funded by the European Union under GA No. 101093171. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union. Neither the European Union nor the granting authority can be held responsible for them.