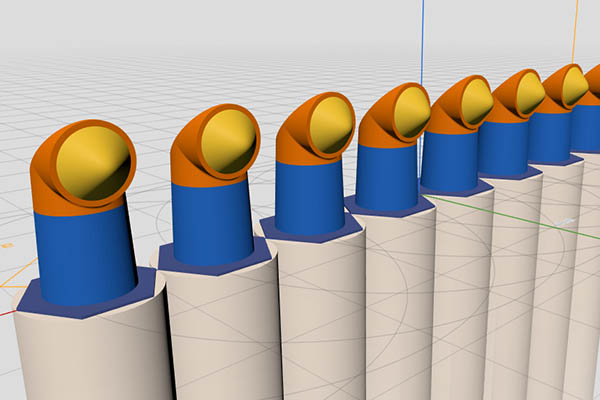

Lensed Fiber Arrays

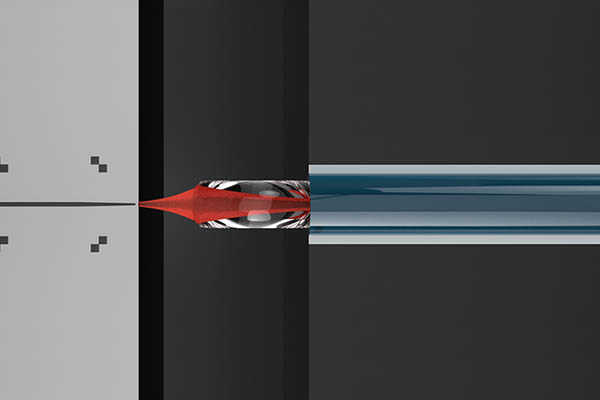

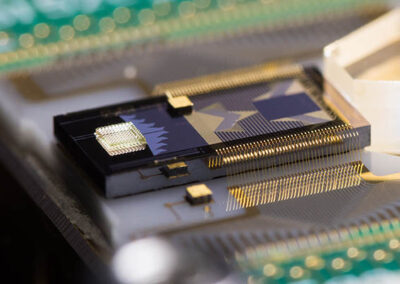

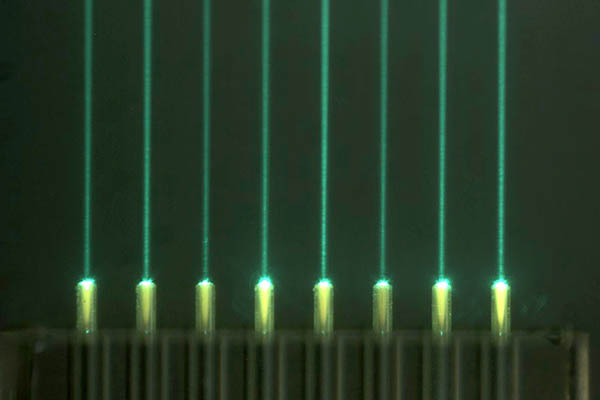

Our lensed fiber arrays (LFAs) are v-groove optical fiber arrays with 3D printed lenses at the ends of the fibers. They are intended for free space coupling to other fiber arrays, photonic integrated circuits (PICs), or other components. The printed microlenses can focus or collimate the light from the fibers, enabling mode field conversion or coupling over larger distances. We can even print periscopic lenses suitable for wafer-level die testing.

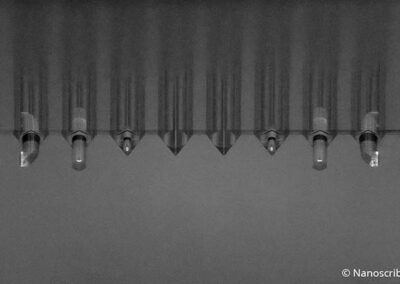

The high-precision 3D printing of lenses is performed on our Nanoscribe Quantum X Align tool. This additive manufacturing process offers many advantages over traditional, subtractive, methods of creating lensed or tapered fibers, such as:

- High positioning accuracy relative to the fiber core

- Full control over lens design parameters, such as asphericity for aberration correction. Even periscopic lenses are possible.

- The ability to print directly onto existing surfaces, enabling more options for light coupling

We have several lensed fiber arrays available in stock and can make custom configurations for you.

Other structures or other surfaces?

How to configure your LFAs

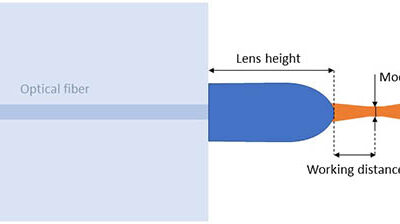

Lensed fiber arrays project light into free space. The lens design allows certain combinations of working distance and the mode field diameter that occurs at the ‘waist’ of the beam. The achievable working distance and mode field diameters depend upon the wavelength and the type of fiber used. The working distance is measured from the top of the lenses and can be up to 100 μm for both focused and collimated beams. The lenses protrude from the fiber array by a maximum of 250 μm.

Note: we can also offer lensed fiber arrays with periscopic mirrors suitable for wafer level testing.

Advantages over traditional lensed or tapered fibers

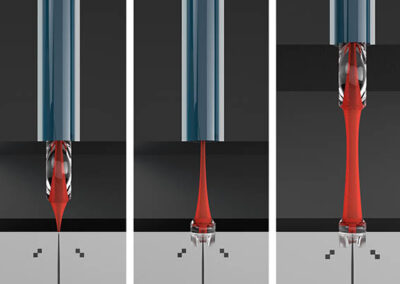

Lensed or tapered fibers are traditionally manufactured using a subtractive process, i.e. grinding, melting or etching. The resulting shapes are limited by the basic process parameters of these techniques. Our lenses, on the other hand, are created using an additive process of high-precision 3D printing using Dip-in Laser Lithography (DiLL) and Two-Photon Polymerization (2PP). This offers much more control over the shape of the lens, allowing aspherical shapes to correct for various aberrations and asymmetric shapes for adapting the beam profile.

An additional advantage of our 3D-printed lenses is that they are created when the fibers are already secured in an array. This avoids length deviations between the individual fibers.

Vs. spot size converters

Both lensed fiber arrays (LFAs) and the PHIX spot size converters (SSCs) can tailor the mode field diameter to improve the coupling of light between fiber arrays and photonic integrated circuits (PICs). There are also some significant differences.

LFAs are suitable for free space operation, for example allowing contactless measurements to be performed. Our SSCs, on the other hand, require a permanent adhesion to the PIC using epoxy. This improves the thermal stability of the optical coupling.

SSCs enable low-loss coupling to PICs due to their lithographically defined waveguides. LFAs face some challenges for coupling to low mode field diameter waveguides, because the placement accuracy of the microlenses is limited by the fiber placement accuracy.

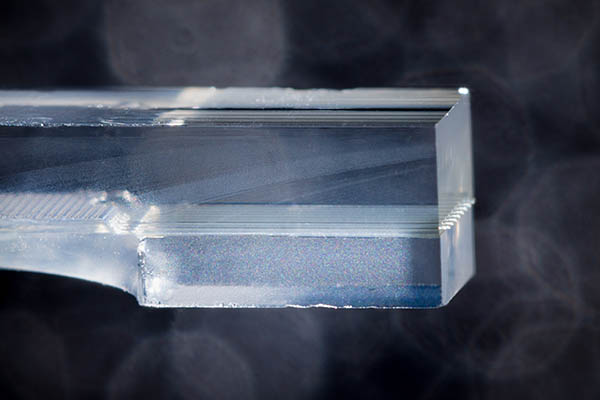

PIC surface printing

Further developments

In order to further improve mode field conversions between fiber arrays and PICs, a process for printing microlenses on the chip facets is currently being developed. These lenses perform mode field conversions on the chip itself, so that much more lenient placement tolerances exist in the free space between the components. This way, the losses due to variations in core concentricity and cladding diameter of the optical fibers can be greatly reduced.

Buy your lensed fiber array

PHIX has a dedicated webshop for (lensed) fiber arrays where you can make your own configurations and have them delivered to you quickly.

“We have a great collaboration with PHIX. As we help PHIX expand their product offering with 3D-printed freeform microlenses, they open up a new market for us and give us valuable feedback on future market requirements.” – Jörg Smolenski (Nanoscribe)

Features

- 3D-printed polymer lenses (up to 250 μm in height)

- Mode field reduction or beam collimation

- Wavelengths ranging from visible to mid-infrared

- Polarization maintaining, horizontal or vertical

- 127 or 250 μm pitch

- 1 up to 32 fibers, several fiber lengths

- FC, LC or MPO connector interface

- UPC or APC connector polishing style

Benefits

- Perfect for PIC characterization or free space operation

- Accurate core pitch position

- Customized solutions available

- Compact design

- Periscopic mirror design available for wafer-level PIC testing